|

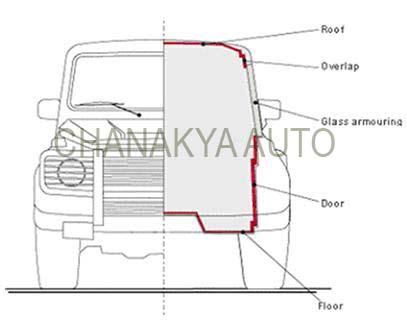

1. Against rifle fire: The car is enveloped in a cocoon of ballistic resistant material capable of withstanding the weapons being fired. Broadly there are transparent and opaque armour (generaly imported armoured steel). Where visibility is required transparent armor is provided and the body is cocooned with opaque armor. Where ever the two meet an overlap is required to be provided. The special skill of the designer is through overlaps and shrapnel traps to cover all gaps in the armour.

Some examples of gaps which are hard to plug are the areas where wires, handles, pipes etc. go from within the protective shell to outside. Some such areas would be where brake, clutch, air-conditioner and other controls move from within the cabin to the engine compartment. Like wise there are controls for opening the doors etc which cause gaps in the doors. The key point is that at no angle should a hostile projectile be able to penetrate the protective shell.

The transparent armor is not just thicker glass as is often perceived. The material is a composite constructed of multilayers. The first layer is a hard brittle material which breaks over a larger area fragmenting the incoming projectile as well as spreading the kinetic energy over a larger area. The second layer is a soft elastic layer which does not fracture but rather buckles inward further spreading the energy over larger area. This is followed by another brittle layer and so on.The last (innermost) layer is made of a flexible material to completely absorb all splinters. The composition and number of layers depend on the threat level we want to protect against. The heavier and faster the bullet, the more layers and hence higher weight and of course cost.

The opaque armor is made from imported armor steel. As a rough estimate this steel is having a penetration resistance of about four times the resistance of mild steel plates. This means that the protection we provide (against SLR) is about the equivalent of one inch thick steel plates all around you.

2. Against Explosive attacks : For protection against explosions the floor and roof are armored. They are then layered with special materials. Each layer absorbs some energy and buckles inward leaving less stress for the next layer. The threat level we desire to protect against will determine the no of layers. Since this is a woven composite, the weft and weave will also factor into our calculations.

3. Against assault on tires : The last layer of defense is against assault on the tires. We change the rims and tires to heavy duty products and fit a run flat insert. This insert will typically keep the vehicle running for a distance of 50 kms at a speed of 50 kmph after absorbing 5 bullets.

Run flat inserts. Complete coverage from every angle of fire will result in an increase in weight of about 900-1000 kgs for SLR protection (depends on the size of cabin).

Almost no standard vehicle can withstand this load. The changes required include strengthening the basic structure, reinforcing the suspensions, increasing engine power to carry extra load, boosting of clutch, brakes, cooling systems etc. In short we need to take the basic vehicle and reengineer a large part of the systems to cater for the increased demands armoring places on the vehicle. All this has to be achived keeping the original performance and reliability of the vehicle virtually unchanged.

There are several non security aspects to armoring as well. Gas sensors are required to ensure that monoxide levels do not build up or oxygen levels do not drop. Many other security aspects which the VIP’s require need to be built into the vehicle at the design stage. These could include GPS systems to track the vehicle, public address systems, radio jammers etc. In addition there are many features which because of their security implications are not possible to divulge. It would not be an exaggeration to state that almost every armored vehicle is a custom built vehicle.